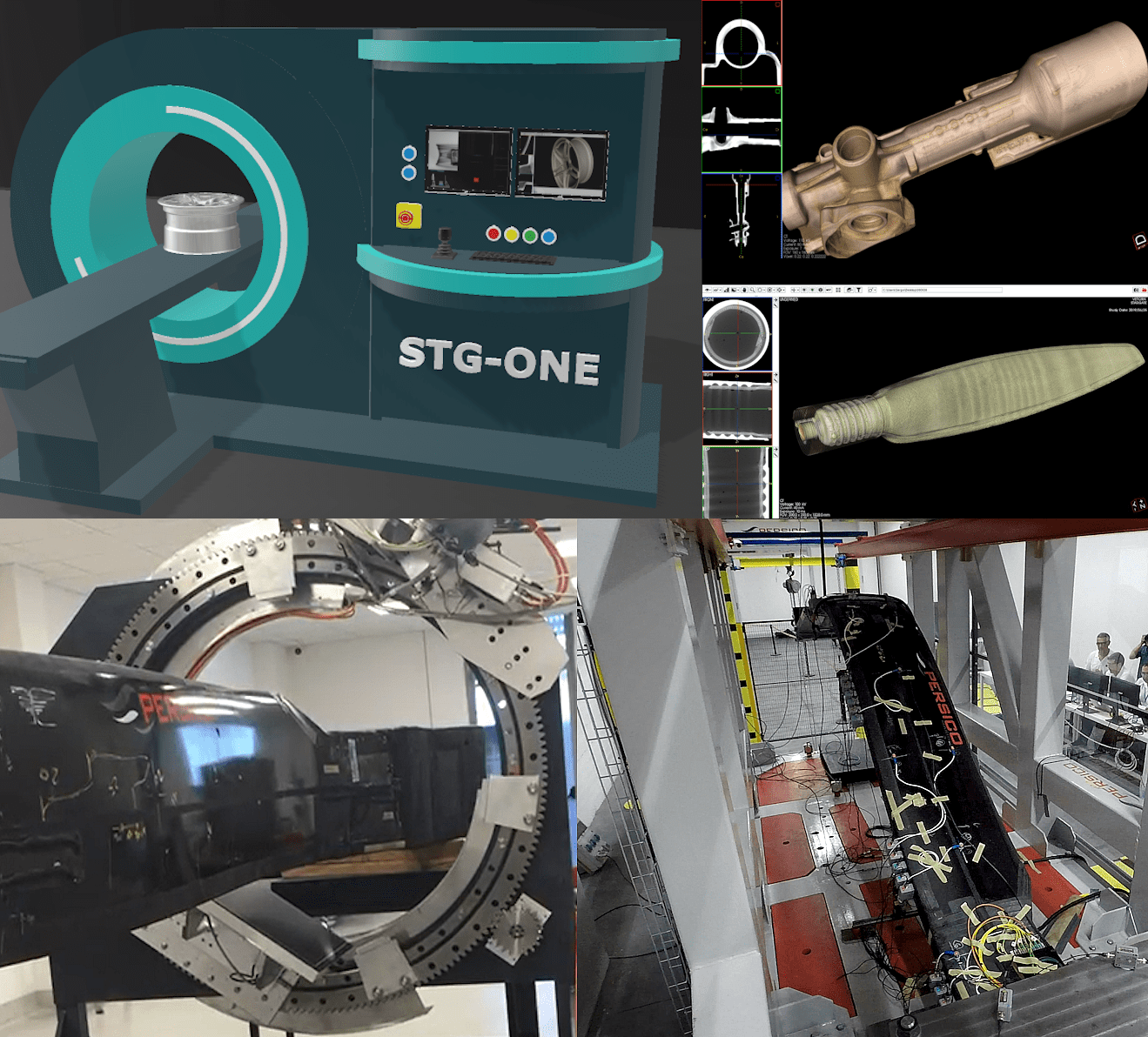

STG CT scanner

Benefits of Tomography & Radiography

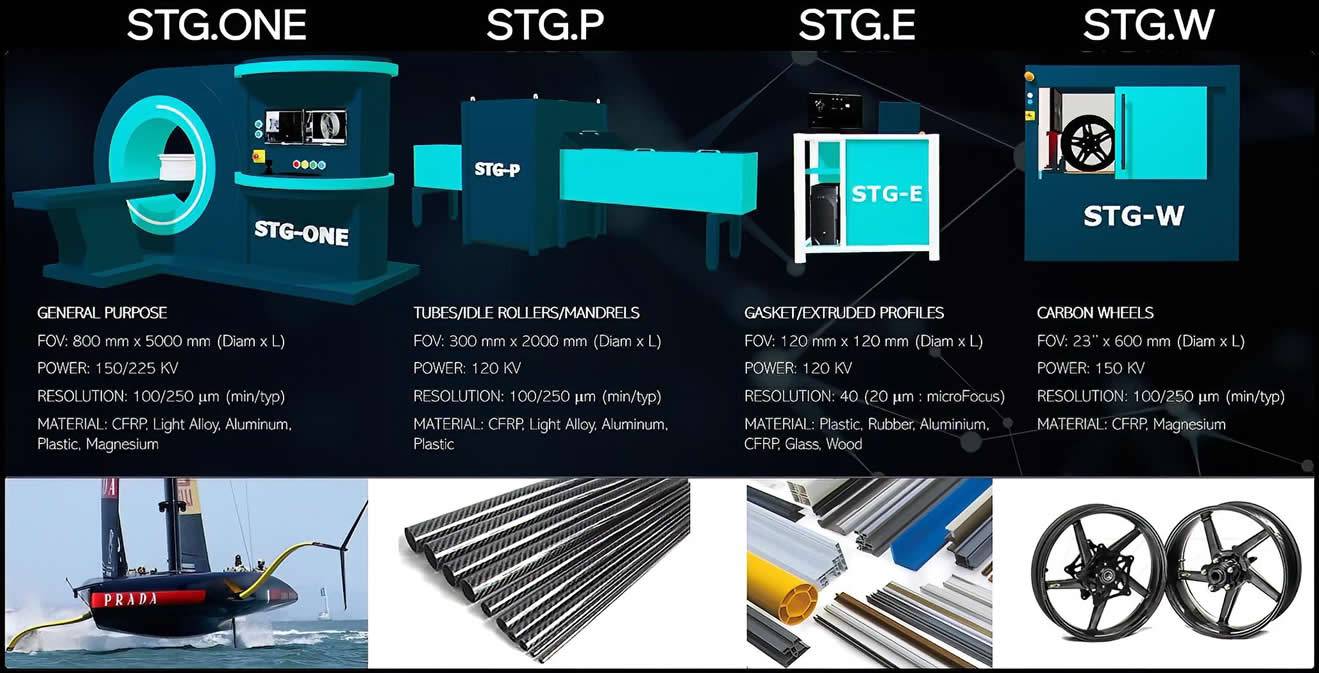

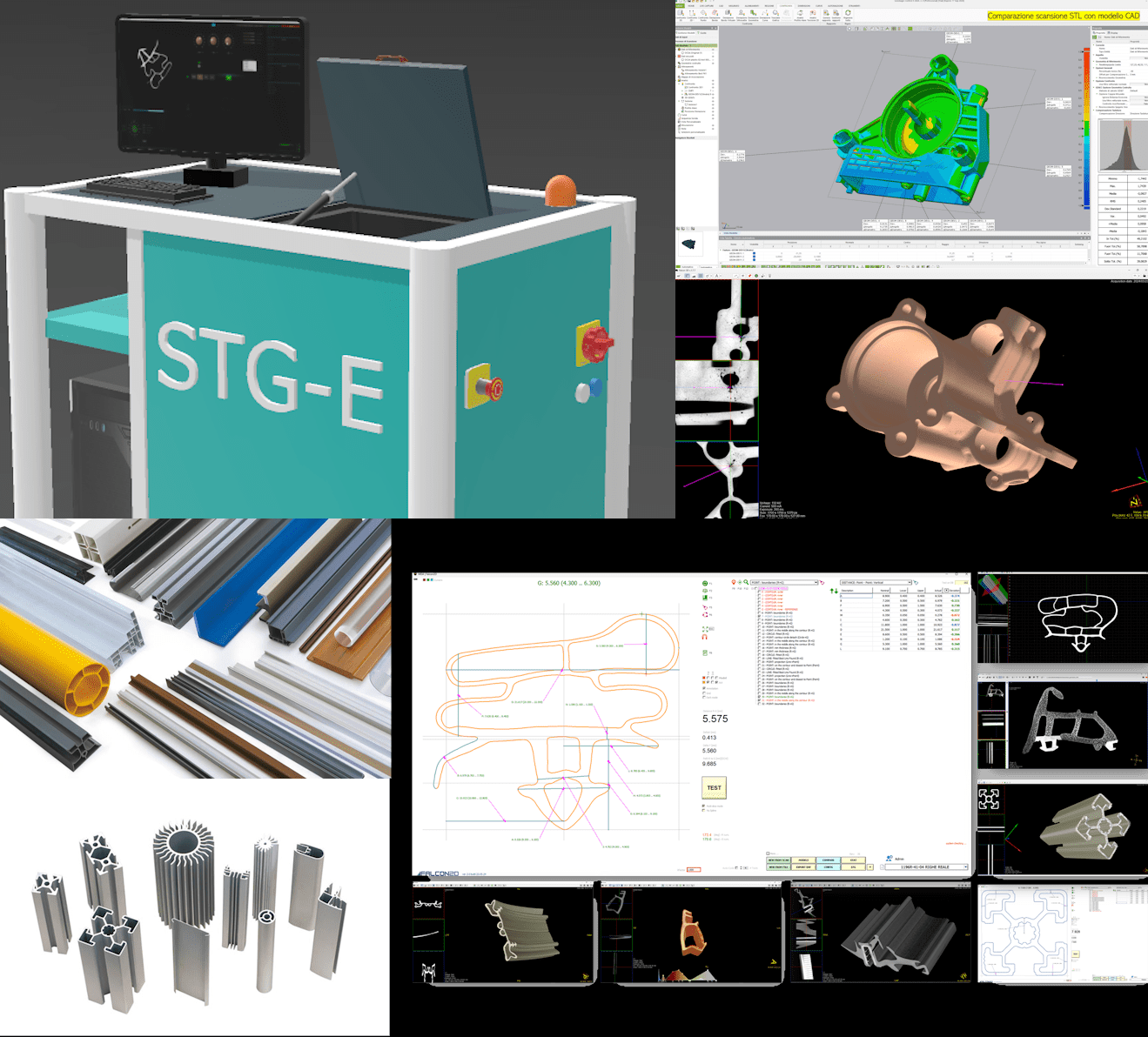

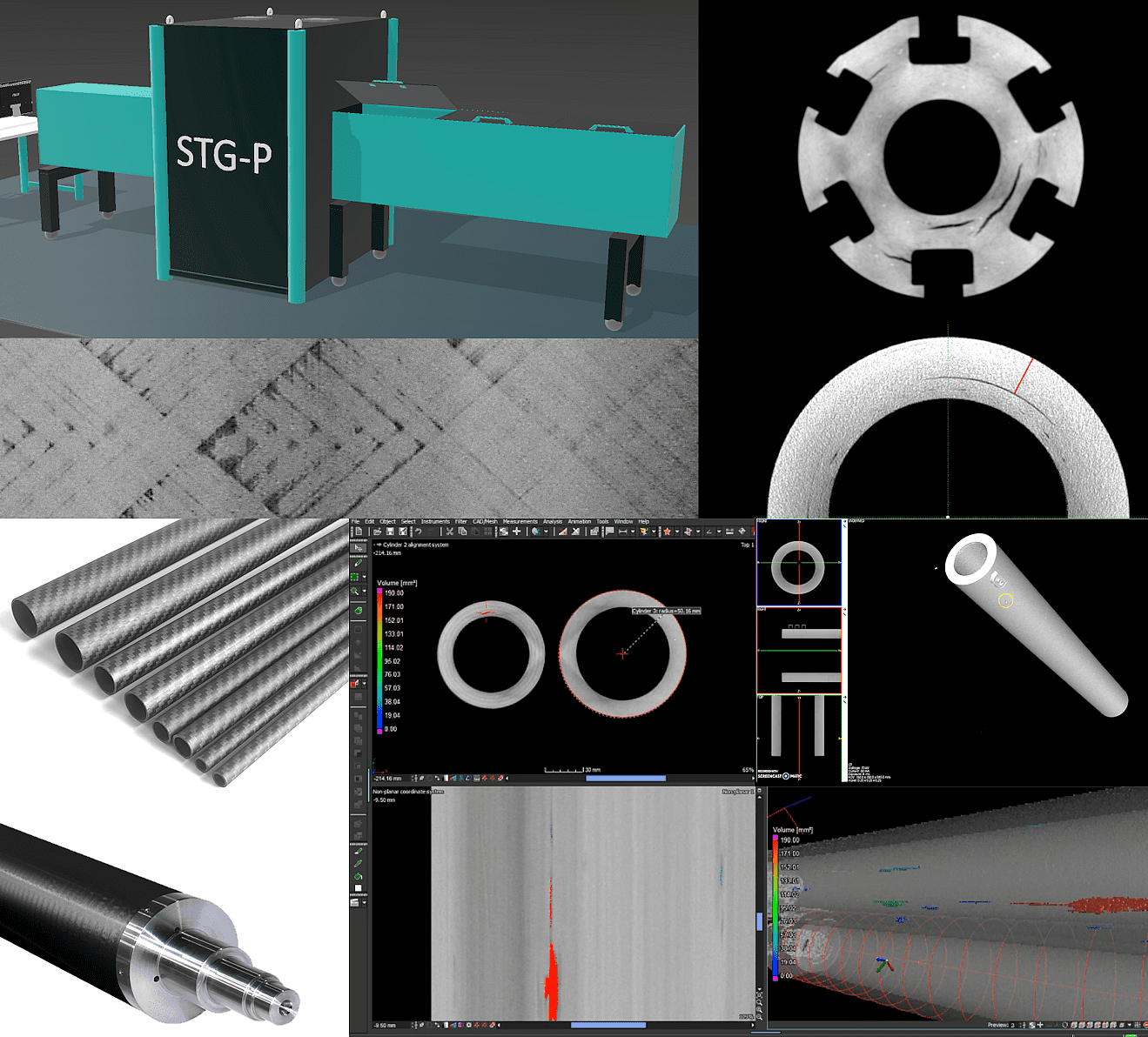

MDA designs and develops industrial tomography machines for special applications. The goal is to bring tomography directly into production environments: lean and easy-to-use machines. 2D metrological or 3D applications for qualitative analysis of the product (porosity, bubbles, cracks) or 3D comparison with CAD models for dimensional checks or missing parts.

STG is a family of 3D tomographic scanners developed specifically for plastic and aluminum products. You can monitor the quality of your products directly online. You can obtain metrological information and 3D models but above all you can see what happens inside your products without having to cut them or send them to external laboratories: all in a few seconds.

Automatic reports, statistical analysis, control charts, integration with your factory network: the software is entirely developed in our laboratories: we can adapt it to your needs.

Comprehensive Insights

Our services deliver comprehensive insights into material integrity, ensuring that you have the information needed to make informed decisions in your operations.

Accurate Imaging

We support decision-making with accurate imaging, providing clarity and confidence in your assessments, whether in healthcare diagnostics or manufacturing quality control.

Versatile Applications

Our tomography and radiography techniques are applicable in various fields, including healthcare and manufacturing, making them essential tools for diverse industries.

STG-E

STG.E: specific for plastic/rubber/aluminium extrusions. By inserting a piece of a few centimetres STG.E will automatically obtain the orthogonal section and compare it with a reference .dxf file.

STG-P

STG-W

STG-ONE

STG.ONE: the top of the range of the family, capable of scanning cylinders with a diameter of 800 mm and over 5 metres long.